Your Recent Search:

3 Problems Contractors Face When Using Low-Bid Blades

July 10, 2018

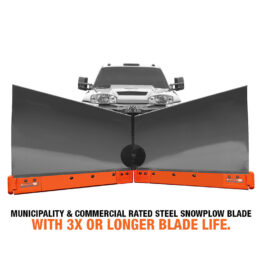

While it can be tempting to grab a cheap plow blade, especially if you are mechanically inclined, doing so can cause big problems for your plow business and cost you way more over time.

Also known as “low-bid blades,” cheap plow blades give you exactly what you pay for. However, in an industry that can experience freezing temperatures, extremely harsh wind chills, and long sleepless nights, blade quality is not something to skimp on.

Here are three problems low-bid blades can cause that negatively affect your operation.

1) Increased Expenses

Low-bid equipment, although less expensive upfront, could end up costing you much more in the future due to repair costs, breakdowns and additional time spent off the roads fixing equipment.

The lost time and money can add up to much more than a few cheap blades.

2) Safety Concerns

While there are always safety concerns involved in plowing, blades that need constant changing put operators in harm’s way more frequently. Operators can be injured during installation of cheap blades that break or that are too heavy to lift.

Additionally, both motorists and snow plow operators can become accident victims due to blades, cast iron shoes or hardware breaking on the plow and spilling onto the roads. This puts sharp, dangerous debris directly in the path of the vehicles during an already risky time to drive.

Choosing a high-quality cutting edge as opposed to a low-bid blade will dramatically reduce the chance of equipment failure-related accidents, thus increasing personal safety and equipment longevity.

3) Extra Man Hours

Changing blades is never time well spent. During a snow event, you need to be out on the road, not in the garage replacing broken, cheap blades!

You can save endless man hours and labor costs when you eliminate the need to repair, adjust, and maintain your plow blades.

Imagine what better and more reliable equipment can do for a smaller contractor operation that puts quite a bit less wear and tear on the gear! Invest in the future of your business by investing in high-quality blades!

Subscribe to our blog

Get notified when we post a new article

"*" indicates required fields